CNC Tool and Die Ltd

Our Machinery and Tooling

CNC Tool & Die, established in 2005, provides precision CNC machining solutions to a range of industries, including aerospace, automotive, defence, medical device, and pharmaceuticals. Based in Lisburn, Northern Ireland, the company offers tailored services designed to meet complex manufacturing challenges.

CNC Machining

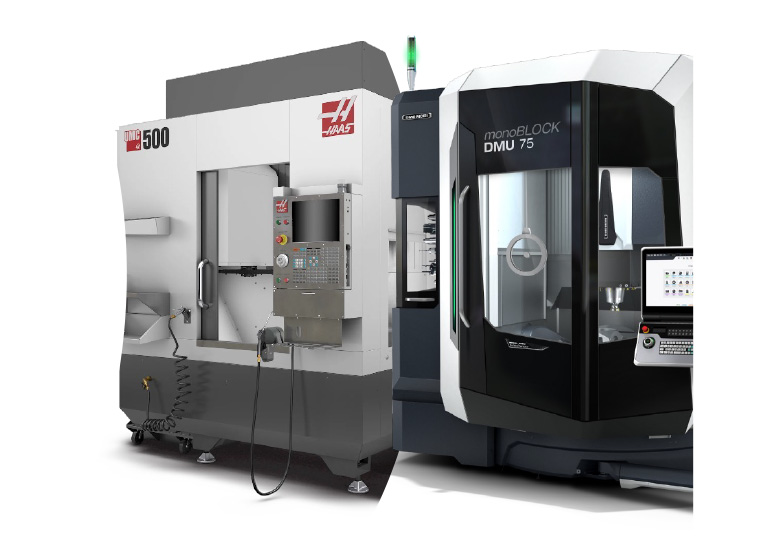

Core services include CNC machining (3-axis, 5-axis, and turning) for producing components from various materials. The company utilises advanced machinery and techniques, including automated systems and CAM programming, to ensure accuracy and efficiency. 3-axis and 5-axis machines incorporate features like Poke-Yoke technology and heat shrink tooling, while turning centres use automatic bar feeds. CAM programming includes tool path simulation, multi-axis machining, and collision avoidance.

CNC Tool & Die is committed to quality, employing stringent quality management systems and CMM verification in a temperature-controlled environment. The company also offers supply chain solutions, such as finishing treatments and procurement options, to provide comprehensive support for its clients’ manufacturing needs.

3-AXIS CNC MACHINING

Table size: 1250mm x 500mm

Can cut a wide selection of materials including:

- Aluminium

- Steels

- Plastics

- Composites

Fitted with Poke-Yoke matrix table technology

Utilises heat shrink tooling for the best precision and repeatability performance

Total of 3 3-Axis CNC Machines

CNC Turning

Machine Limits: ø80mm x 1000mm

Can cut a wide selection of materials including:

- Aluminium

- Steels

- Plastics

- Composites

Fitted automatic bar feed for continuous batch manufacture

Total of 2 CNC Turning Centers

5-AXIS CNC MACHINING

Table size: 650mm x 650mm

Can cut a wide selection of materials including:

- Aluminium

- Steels

- Plastics

- Composites

Fitted with Poke-Yoke matrix table technology

Utilises heat shrink tooling for the best precision and repeatability performance

Total of 3 5-Axis CNC Machines

Automated CNC MACHINING

- 1 x 3-Axis (5 pallet) – 1250x500mm

- 1 x 5-Axis (18 pallet) – 500x500mm

- Advanced CNC Machining Technology

- Increased Production Uptime and Efficiency

- Reduced Labor Costs and Improved Consistency

CNC PROGRAMMING (CAM)

- The most optimised tool path simulation technology to reduce risk of errors

- Multi-axis machining for complex, single-setup part production

- Automated feature recognition to accelerate programming and reduce lead times

- Advanced collision avoidance algorithms for safer, more efficient machining

- Integrated CAD/CAM workflows for seamless design-to-production transitions