CNC Tool and Die Ltd

Our Services

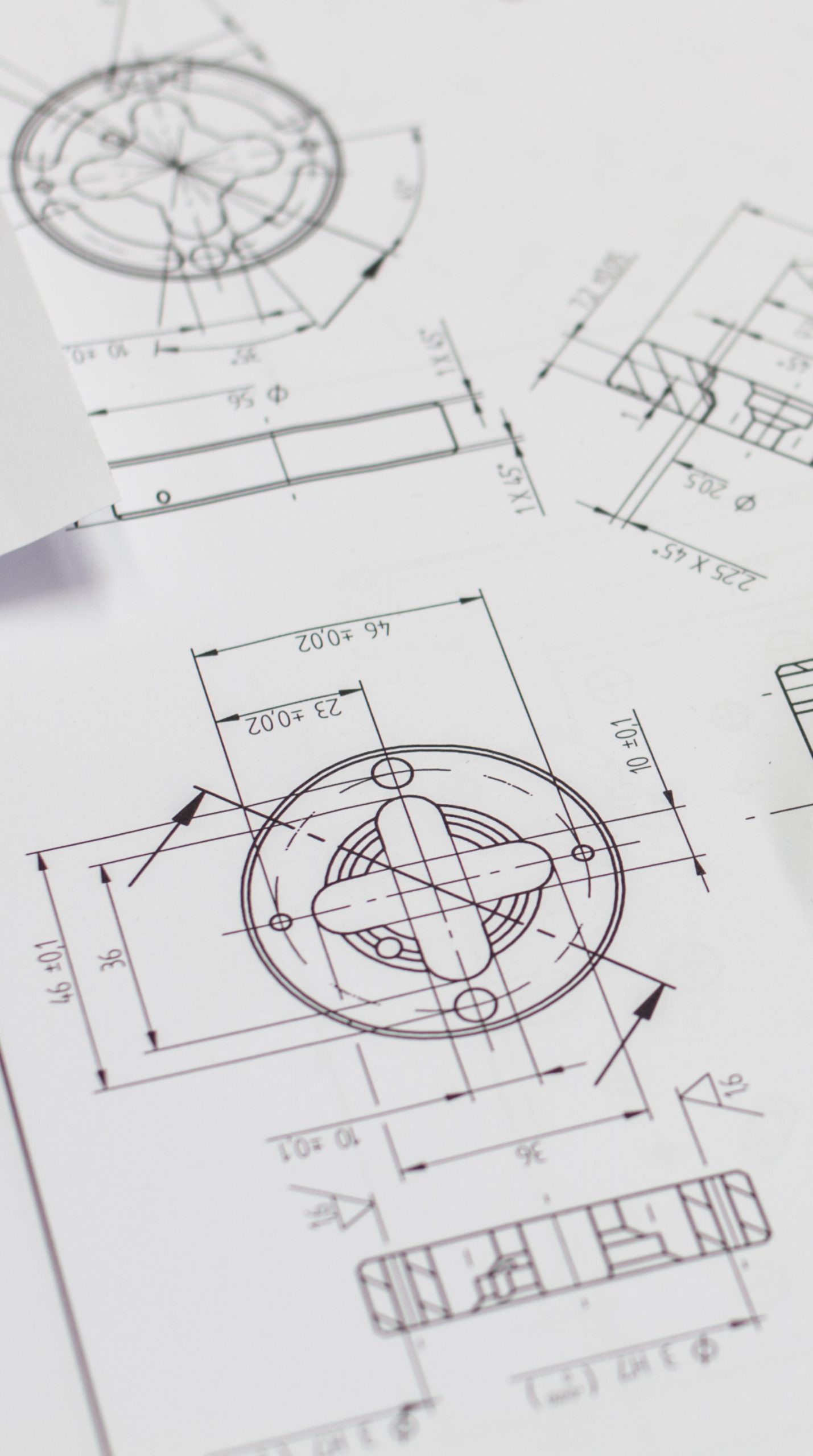

CNC Tool & Die provides a comprehensive suite of precision engineering services, focused on delivering high-quality, tailored solutions to meet the diverse and demanding needs of modern manufacturing. With expertise honed over two decades, the company specialises in CNC machining and related capabilities, serving critical industries such as aerospace, automotive, defence, medical device, and pharmaceuticals.

CNC Machining

At the core of CNC Tool & Die’s service offering is its CNC machining capability. The company offers 3-axis, 5-axis, and CNC turning services, enabling the production of components with varying levels of complexity and precision. 3-axis machining provides a foundation for efficient and accurate production of a wide array of parts from various materials, including aluminium, steel, plastics, and composites. For more intricate geometries and demanding specifications, 5-axis machining allows for the manufacture of complex components in a single setup, enhancing accuracy and reducing lead times. CNC turning complements these milling capabilities, providing precision cylindrical machining for components requiring rotational symmetry.

Automated CNC Machining

Recognising the importance of efficiency and productivity in modern manufacturing, CNC Tool & Die also offers automated CNC machining solutions. This service is designed to maximise production uptime, increase efficiency, and improve consistency while reducing labour costs. By automating the loading and unloading of parts, CNC Tool & Die can deliver higher volumes of components with greater precision and shorter lead times.

CNC Programming Services

Beyond machining, CNC Tool & Die provides comprehensive CNC programming (CAM) services. This crucial aspect of the manufacturing process involves the creation of optimised tool paths to guide the CNC machines, ensuring accuracy and efficiency. The company utilises advanced CAM software with features such as multi-axis machining capabilities, automated feature recognition, and collision avoidance algorithms. These advanced programming techniques enable the production of complex parts, reduce programming time, and minimise the risk of errors during machining.

Quality – CMM (Coordinate Measuring Machine)

Quality is paramount at CNC Tool & Die, and the company implements stringent quality management systems to ensure that all components meet the precise specifications of its clients. This commitment to quality is upheld through meticulous inspection and quality control processes at every stage of production, along with comprehensive traceability and documentation. To further enhance accuracy and verification, CNC Tool & Die employs CMM (Coordinate Measuring Machine) verification in a temperature-controlled environment.

CNC Tool and Die Ltd

In addition to its core machining and programming services, CNC Tool & Die offers a range of supply chain solutions to provide clients with a comprehensive manufacturing service. These solutions include:

Finishing Treatments:

A variety of finishing processes to enhance the properties and appearance of manufactured components, such as powder coating, anodising, and plating.

Advanced Manufacturing Processes:

Access to complementary manufacturing technologies, including laser/waterjet cutting and electrical discharge machining (EDM), through trusted partners.

Procurement Solutions:

Material sourcing and supply chain control to ensure the timely and cost-effective delivery of projects.