Quality

CNC Tool and Die Ltd

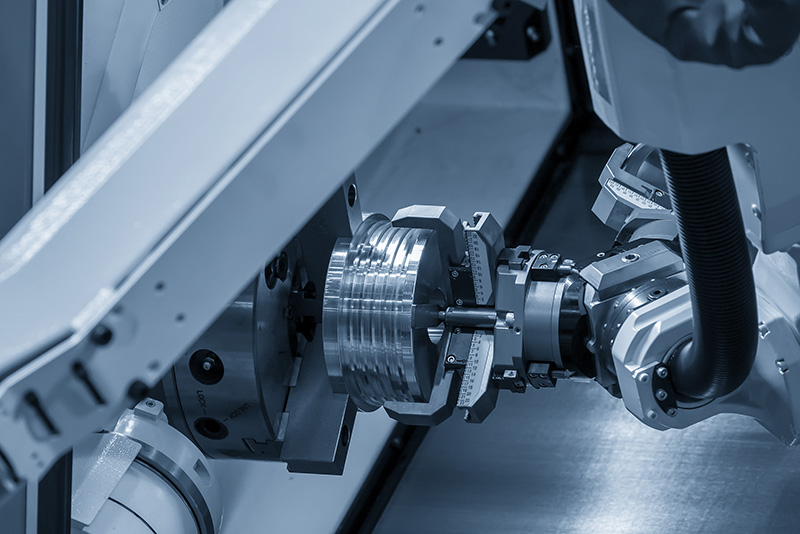

At CNC Tool & Die, quality is fundamental to our operations and a cornerstone of our commitment to our clients. We understand that the industries we serve, including aerospace, defence, and medical devices, demand the highest levels of precision, reliability, and traceability. To meet and exceed these expectations, we have established a comprehensive quality management system that governs every aspect of our manufacturing processes.

CNC Tool & Die Quality

Stringent Quality Management Systems

We adhere to the most stringent quality management system standards required by the aerospace and defence industries. CNC Tool & Die have maintained AS9100 Rev D certification since 2022. This commitment guarantees the precision, reliability, and traceability of every component we produce. Our dedication to quality is reflected in our active participation within a network of industry leaders focused on driving excellence and innovation. This involvement ensures that we remain aligned with industry best practices and are always striving for improvement.

CNC Tool and Die Ltd

the approach we follow

A quality approach in engineering emphasises systematic planning, continuous

improvement, and adherence to standards to ensure reliable, efficient, and safe product.

Meticulous Inspection and Control

CNC Tool & Die implements meticulous inspection and quality control processes at every stage of production. From the initial material sourcing to the final product inspection, we maintain rigorous control to ensure that every component meets or surpasses the precise specifications of our clients. This involves detailed checks, measurements, and testing to identify and rectify any deviations from the required standards.

CMM Verification

Our commitment to precision is further demonstrated by our advanced CMM (Coordinate Measuring Machine) verification capabilities. Our CMM operates within a temperature-controlled environment, ensuring optimal stability and accuracy. The specifications of our CMM are:

Capacity: 710mm (X) x 1010mm (Y) x 680mm (Z)

Repeatability: ~1μm (0.001mm)

Accuracy: ~4μm (0.004mm)

The use of this technology allows us to achieve improved FAIRs (First Article Inspection Reports) in compliance with AS9102 standards. We utilise the latest version of PC-DMIS software to maximise the effectiveness of our CMM verification processes.

Traceability and Documentation

Luisque cursus metus vitae sed pharetra auctor semy mas interdum venenatis tristique egets diam. Vestibulum ante ipsum faucibus luctus ultrice posuere libero eget ante cubilia.

Continuous Improvement

CNC Tool & Die is dedicated to streamlining processes, enhancing efficiency, and delivering exceptional value through a robust and reliable supply chain. We operate a Continuous Improvement Plan based on the Plan-Do-Check-Act cycle. This involves:

– Plan: We plan to exceed customer requirements and expectations.

– Do: We execute internal controlled processes.

– Check: We actively seek improvement opportunities.

– Act: We implement actions for controlled and sustained business improvement.

Through this systematic approach, we continually refine our operations to optimise performance and customer satisfaction.

At CNC Tool & Die, our unwavering commitment to quality underpins our pursuit of excellence in precision machining.